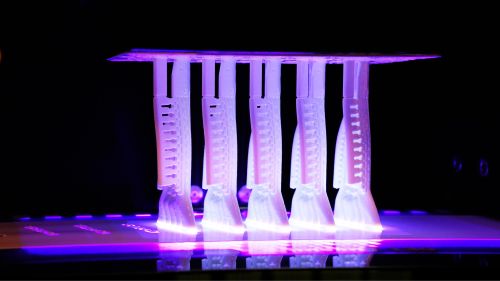

Featuring the unique capability of 3D printing both advanced ceramics and metals on one system. This technology is ideal for the development and 24/7 digital serial production of functional and aesthetical parts requiring complex geometries, high resolution, fine details, and smooth surface while benefiting from excellent material properties.

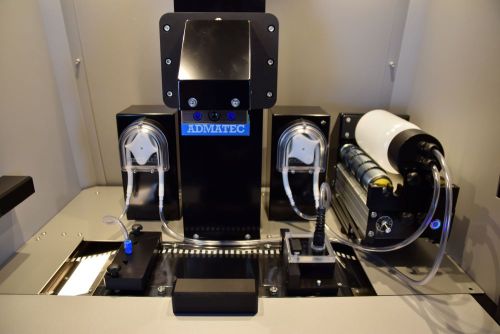

With up to 300 printed layers per hour, the Admaflex 130 Evolution is the fastest and most efficient ceramic 3D printer available on the market today. High production speeds are possible due to the smart feedstock supply system, which is designed to effectively handle materials with high viscosity, normally associated with ceramic and metal slurries. All machines come standard with a reliable high power WQXGA light engine, controlled and monitored by the software. A vision-based, in-process quality monitoring system is integrated for full traceability of the printing process. Our printing technology is patented with US patent number 11,141,909. A very small amount of slurry is sufficient to start printing, which makes the system ideal for research and 3D printing of precious materials.

With up to 300 printed layers per hour, the Admaflex 130 Evolution is the fastest and most efficient ceramic 3D printer available on the market today. High production speeds are possible due to the smart feedstock supply system, which is designed to effectively handle materials with high viscosity, normally associated with ceramic and metal slurries. All machines come standard with a reliable high power WQXGA light engine, controlled and monitored by the software. A vision-based, in-process quality monitoring system is integrated for full traceability of the printing process. Our printing technology is patented with US patent number 11,141,909. A very small amount of slurry is sufficient to start printing, which makes the system ideal for research and 3D printing of precious materials.

The Admaflex 130 Evolution comes standard with ceramic ánd metal printing capabilities. An integrated high volume automatic mixing system keeps the material in motion, avoiding sedimentation. The Admaflex 130 3D printer is the world’s first stereo lithography based 3D printer to print metals and ceramics in one platform. The Admaflex 130 3D printers built from 2016 to 2022 can be upgraded with an Add-on for printing metals and other heavy powders.

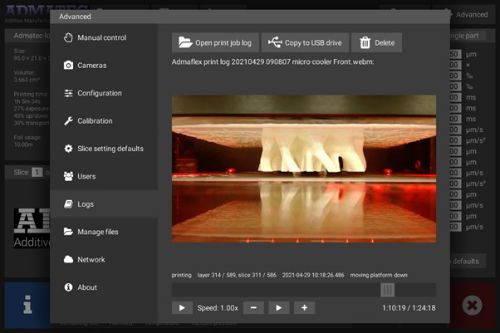

The vision-based in-process quality monitoring system is an excellent feature for full traceability of the printing process. All relevant production data are stored in logfiles with documented proof of the printing process. Real-time video capture and time-lapse recording are standard features of the monitoring system. It allows the user, for example, to partially stop adding layers to a defective product to allow the successful finalization of all remaining parts. When the Admaflex machine is connected via Ethernet to your company network, via any laptop or desktop PC, you can have remote access to the machine and monitor the process in real-time.

| Technology |

Digital Light Processing (DLP), |

|

Printing build volume (X,Y,Z) |

64 x 40 x 400 mm | 2.51 x 1.57 x 15.7 inch (25 μm) |

|

Light engine type |

High power WQXGA light engine with 2560 x 1600 pixels |

|

Layer thickness |

10 - 200 µm, depending on material type |

|

Build speed (layers/h) |

Up to 300 layers per hour |

|

Build speed (mm/h) |

Up to 60 mm/h, depending on material type |

|

Wall thickness |

0.1 - 10 mm in alumina |

|

Material Container volume |

1200 ml |

|

Build platform fixture |

zero-point clamping |

|

Machine dimension (WxDxH) |

980 x 670 x 1880 mm | 38.5 x 26.37 x 74 inches |

|

Weight |

ca. 300 kg | 660 lbs |

|

Required working temperature |

22 +/- 2°C |

|

Required working humidity |

< 40% |

|

Connectivity |

Ethernet, USB |

|

Power requirements |

110 / 230 V |

|

File compatibility |

SLC, STL |

|

Final product density |

Technical ceramics > 98.5% - 99.8%* |